- Jiangyin Gaohong Machinery Manufacturing Co., Ltd.

- 1100

- 2022-03-28

Equipped with a hopper mixer and multiple mixing hoppers of different specifications, it can meet the mixing requirements of various varieties and different batches, and it is an ideal equipment for pharmaceutical factory mixing.

Detailed information

Purpose:

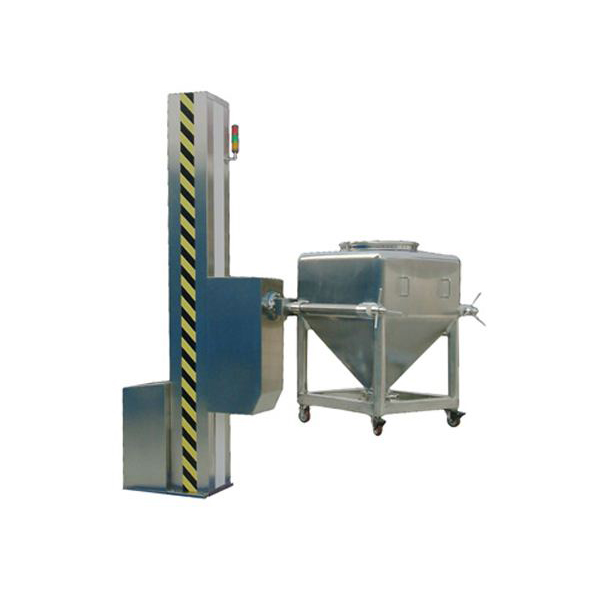

The machine has the functions of automatic lifting, mixing and lowering. Equipped with a hopper mixer and multiple mixing hoppers of different specifications, it can meet the mixing requirements of various varieties and different batches, and it is an ideal equipment for pharmaceutical factory mixing. At the same time, it is widely used in pharmaceutical, chemical, food and other industries.

Rationale:

The machine is composed of upright column, machine base, slewing fork, drive, brake, control system and other components. Push the mixing hopper into the slewing fork and lock the nut, start the control system, lift the hopper to the mixing height and position it reliably. The drive system automatically mixes according to the set time, speed and other data. When the mixing operation ends, the rotary fork stops vertically, the hopper automatically descends to the ground, the whole machine stops, and the process data is printed. Loosen the lock nut of the slewing fork and push the hopper out to the next process.

Features:

This machine is a new model that our company has extensively absorbed and digested foreign technology and successfully developed it in combination with domestic market conditions. After mixing, the hopper can continue to be raised to the height required by the process, which is convenient for discharging. The whole machine has reasonable structure, stable performance and convenient operation. No dead ends, no exposed screws. The rotary body (mixing hopper) forms an included angle of 30° with the rotary axis. The material in the mixing hopper flips with the rotary body and moves tangentially along the hopper wall, resulting in strong turning and high-speed tangential movement, so as to achieve the best results. blending effect. It adopts PLC automatic control, and is equipped with an infrared safety device and a discharge butterfly valve with an anti-misoperation device to ensure production safety. Materials can pass through different process sections in the same container without frequent transfer, feeding and other procedures. Effectively control dust and cross-contamination, reduce material loss, control material stratification, optimize production process, and fully meet GMP requirements for drug production.

Main technical parameters:

|

型号Model |

混合转速Mixing speed (rpm) |

最大料斗容积Maximum hopper volume( L) |

最大装料容积Maximum loading capacity (L) |

最大装料重量Maximum loading weight (kg) |

总功率The total power (kw) |

外形尺寸Overall dimensions(长L×宽W×高H)(mm) |

整机重量Weight (kg) |

|

GH-50 |

3~20 |

50 |

40 |

25 |

3.7 |

2045×1400×200 |

600 |

|

GH-100 |

3~20 |

100 |

80 |

50 |

3.7 |

2045×1400×200 |

700 |

|

GH-200 |

3~20 |

200 |

160 |

100 |

4.4 |

2260×1800×2300 |

800 |

|

GH-300 |

3~20 |

300 |

240 |

150 |

5.2 |

2457×2000×2300 |

900 |

|

GH-400 |

3~20 |

400 |

320 |

200 |

5.2 |

2555×2100×2400 |

1000 |

|

GH-500 |

3~15 |

500 |

400 |

250 |

5.2 |

2595×2300×2500 |

1200 |

|

GH-600 |

3~15 |

600 |

480 |

300 |

5.2 |

2663×2400×2500 |

1300 |

|

GH-800 |

3~15 |

800 |

640 |

400 |

7 |

2800×2500×2500 |

1600 |

|

GH-1000 |

3~10 |

1000 |

800 |

500 |

7 |

3020×2700×2900 |

2000 |

|

GH-2000 |

2~8 |

1200 |

960 |

550 |

7 |

3150×2800×4250 |

2200 |