- Jiangyin Gaohong Machinery Manufacturing Co., Ltd.

- 1163

- 2022-03-28

The special wedge-shaped stirring heat transfer blade in the equipment has high heat transfer efficiency and self-cleaning function of the heat transfer surface.

Detailed information

Overview Descriptions

On the basis of absorbing advanced technology at home and abroad, the company has improved and optimized the design of the wedge-shaped hollow blade dryer, which can indirectly heat or cool paste, granular, powder and slurry materials, and can complete drying and cooling. , heating, sterilization, reaction, low temperature calcination and other unit operations. The special wedge-shaped stirring heat transfer blade in the equipment has high heat transfer efficiency and self-cleaning function of the heat transfer surface.

Principle Principle

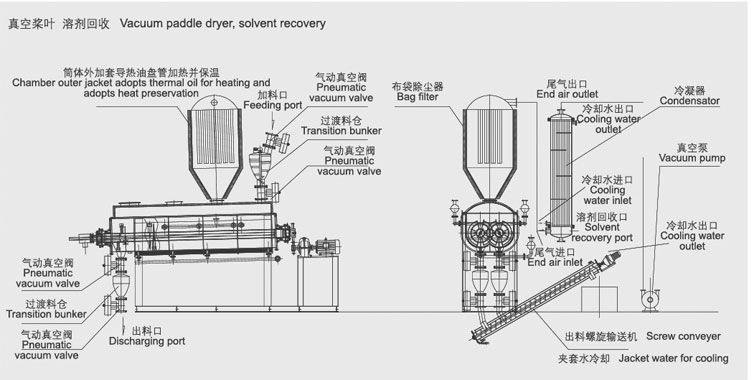

Wedge-shaped hollow blades are densely arranged on the hollow shaft, and the heat medium flows through the blades through the hollow shaft. The heat transfer area per unit of effective volume is large, and the temperature of the heat medium ranges from -40°C to 320°C, which can be water vapor or liquid: such as hot water, heat transfer oil, etc. Indirect conduction heating, no air is carried to take away the heat, and the heat is used to heat the material. The heat loss is only the heat dissipation to the environment through the insulation layer of the body. The heat transfer surface of the wedge-shaped blade has a self-cleaning function. The relative movement of the material particles and the wedge surface produces a scrubbing effect, which can wash off the materials attached to the wedge surface, so that a clean heat transfer surface is always maintained during operation. The shell of the paddle dryer is W-shaped, and two to four hollow stirring shafts are generally arranged in the shell. The shell has a sealed end cover and an upper cover to prevent material dust from leaking out and collect material solvent vapor. A stop lever is set at the discharge port to ensure the height of the material level, so that the heat transfer surface is covered by the material and fully functional. The heat medium flows through the shell jacket and the hollow stirring shaft through the rotary joint. The hollow stirring shaft has different internal structures according to the type of heat medium to ensure the best heat transfer effect.

Sketch of structure

FeaturesFeatures

1. The prize leaf dryer has low energy consumption: due to indirect heating, there is no large amount of air carried to take away heat, and the outer wall of the dryer is provided with an insulating layer. For paddle-shaped materials, only 1.22kg of water vapor is needed to evaporate 1kg of water.

2. The cost of the prize leaf dryer system is low: there is a huge heat transfer surface per unit of effective volume, which shortens the processing time. The smaller size of the equipment greatly reduces the building area and building space.

3. Wide range of processing materials: using different heat media, it can handle both heat-sensitive materials and materials that require high temperature treatment. Commonly used media are: water vapor, heat transfer oil, hot water, cooling water, etc. It can be operated continuously or intermittently, and can be used in many fields.

4. Small environmental pollution: no carry-on air is used, and there is little dust material entrainment. The evaporation of the material solvent is very small, which is easy to handle. Closed-circuit circulation can be used for polluted materials or conditions that require solvent recovery.

5. Low operating cost: The equipment operates normally, only 1-2 people per day. Low speed stirring and reasonable structure. Low wear and tear, low maintenance costs.

6. Stable operation: due to the special compression-expansion stirring effect of the wedge-shaped blade, the material particles are fully in contact with the heat transfer surface.

The degree of synthesis gradient is very small, thus ensuring the stability of the process.

Technical parameters

|

model |

GH-2.7 |

GH-9 |

GH-13 |

GH-18 |

GH-24 |

GH-29 |

GH-36 |

GH-41 |

|

Heat transfer area m² |

2.7 |

9 |

13 |

18 |

24 |

29 |

36 |

41 |

|

Effective volume m³ |

0.06 |

0.32 |

0.59 |

1.09 |

1.53 |

1.85 |

2.42 |

2.8 |

|

Speed range rpm |

15-30 |

10-25 |

10-25 |

15-30 |

10-20 |

10-20 |

10-20 |

10-20 |

|

Power kw |

2.2 |

3.8 |

5.5 |

7.5 |

11 |

11 |

15 |

15 |

|

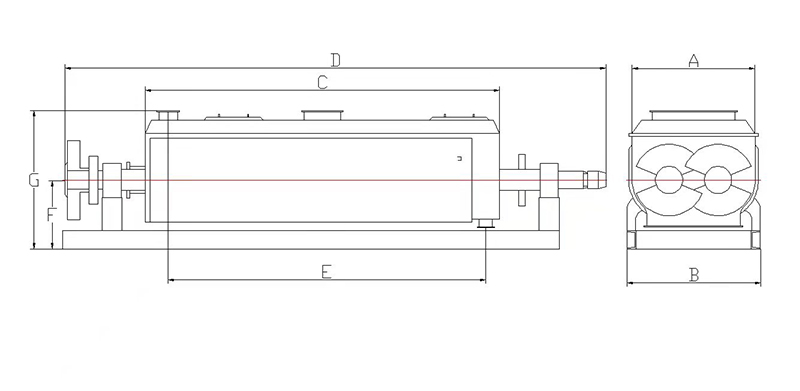

Body width A mm |

306 |

584 |

762 |

940 |

1118 |

1118 |

1296 |

1296 |

|

Overall width B mm |

736 |

841 |

1066 |

1320 |

1474 |

1474 |

1676 |

1676 |

|

Body length C mm |

1956 |

2820 |

3048 |

3328 |

3454 |

4114 |

4115 |

4724 |

|

Overall length D mm |

2972 |

4876 |

5486 |

5918 |

6147 |

6808 |

6960 |

7570 |

|

Infeed and outfeed distance E mm |

1752 |

2540 |

2768 |

3048 |

3150 |

3810 |

3810 |

4420 |

|

Center height F mm |

380 |

380 |

534 |

610 |

762 |

762 |

915 |

915 |

|

Overall height G mm |

762 |

838 |

1092 |

1270 |

1524 |

1524 |

1778 |

1778 |

|

Air intake N |

(2)3/4 |

(2)3/4 |

(2) 1 |

(2) 1 |

(2) 1 |

(2) 1 |

(2) 1 |

(2) 1 |

|

Outlet O |

(2)3/4 |

(2)3/4 |

(2) 1 |

(2) 1 |

(2) 1 |

(2) 1 |

(2) 1 |

(2) 1 |

|

model |

GH-48 |

GH-52 |

GH-62 |

GH-68 |

GH-73 |

GH-81 |

GH-87 |

GH-95 |

GH-110 |

|

Heat transfer area m² |

48 |

52 |

62 |

68 |

73 |

81 |

87 |

95 |

110 |

|

Effective volume m³ |

3.54 |

3.96 |

4.79 |

5.21 |

5.78 |

6.43 |

7.39 |

8.07 |

9.46 |

|

Speed range rpm |

10-20 |

10-20 |

10-20 |

10-20 |

5-15 |

5-15 |

5-15 |

5-15 |

5-10 |

|

Power kw |

30 |

30 |

45 |

45 |

55 |

55 |

75 |

75 |

95 |

|

Body width A mm |

1374 |

1474 |

1651 |

1652 |

1828 |

1828 |

2032 |

2032 |

2210 |

|

Overall width B mm |

1854 |

1854 |

2134 |

2134 |

2286 |

2286 |

2438 |

2438 |

2668 |

|

Body length C mm |

4724 |

5258 |

5410 |

5842 |

5461 |

6020 |

5537 |

6124 |

6122 |

|

Overall length D mm |

7772 |

8306 |

8865 |

9296 |

9119 |

9678 |

9119 |

9704 |

9880 |

|

Infeed and outfeed distance E mm |

4420 |

4954 |

4953 |

5384 |

5004 |

5562 |

5080 |

5664 |

5664 |

|

Center height F mm |

1066 |

1066 |

1220 |

1220 |

1220 |

1220 |

1220 |

1220 |

1220 |

|

Overall height G mm |

2032 |

2032 |

2362 |

2362 |

2464 |

2464 |

2566 |

2566 |

2668 |

|

Air intake N |

(2)11/2 |

(2)11/2 |

(2)11/2 |

(2)11/2 |

(2)11/2 |

(2)11/2 |

(2) 2 |

(2) 2 |

(2) 2 |

|

Outlet O |

(2)11/2 |

(2)11/2 |

(2)11/2 |

(2)11/2 |

(2)11/2 |

(2)11/2 |

(2) 2 |

(2) 2 |

(2) 2 |