- Jiangyin Gaohong Machinery Manufacturing Co., Ltd.

- 1005

- 2022-03-28

Detailed information

Overview:

Spray drying is the most widely used process in the liquid process forming and drying industry. GH series high-speed centrifugal spray dryers are most suitable for producing powdery and granular solid products from solutions, emulsions, suspensions and pumpable pasty liquid raw materials. Therefore, spray drying is an ideal process when the particle size distribution, residual water content, bulk density and particle shape of the finished product must meet precise standards.

Principle and Features:

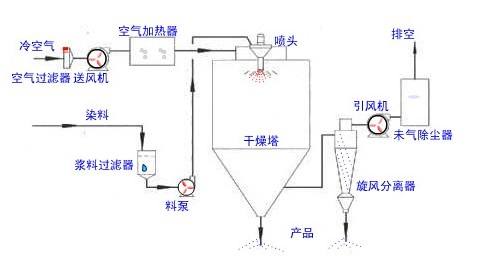

The air of the GH series high-speed centrifugal spray dryer is filtered and heated, and enters the air distributor at the top of the dryer. The hot air enters the drying chamber uniformly in a spiral shape. The fine mist-like liquid droplets are in co-current contact with hot air, and can be dried into finished products in a very short time. The finished product is continuously discharged from the bottom of the drying tower and the output waste gas from the cyclone separator is evacuated by the fan.

Features:

1. GH series high-speed centrifugal spray dryer has a fast drying speed. The surface area of the material liquid is greatly increased after atomization. In the hot air flow, 95%-98% of the water can be evaporated instantly, and the drying time is only a few seconds. It is especially suitable for heat-sensitive drying of materials.

2. GH series high-speed centrifugal spray dryer products have good uniformity, fluidity and solubility, and product purity and high quality.

3. The production process of LPG series high-speed centrifugal spray dryer is simplified and the operation and control are convenient. For liquids with a moisture content of 40-60% (up to 90% for special materials), it can be dried into powder products at one time, and it does not need to be pulverized and screened after drying. It is very convenient to reduce production processes, improve product purity, and adjust, control and manage product particle size, bulk density, and moisture within a certain range by changing operating conditions.

Main technical parameters:

|

Model |

GH-5 |

GH-25 |

GH-50 |

GH-100 |

GH-150 |

GH-200-2000 |

|

Inlet temperature (℃) |

140-350自控 |

|||||

|

Outlet temperature (℃) |

80-90 |

|||||

|

The maximum evaporation of water(kg/h) |

5 |

25 |

50 |

100 |

150 |

200-2000 |

|

Rotating speed(r/min) |

2500 |

18000 |

18000 |

18000 |

15000 |

8000-15000 |

|

Spray disc diameter(mm) |

50 |

120 |

120 |

140 |

150 |

180-240 |

|

Electric heating power(kw) |

9 |

36 |

63 |

81 |

99 |

120 |

|

Heat source |

Electricity |

Steam + Electric |

Steam + Electricity, Oil, Gas, Hot Air Stove |

|||

|

Dimensions (L×W×H) m |

1.8×0.93×2.2 |

3×2.7×4.26 |

3.5×3.5×4.8 |

4.6×4.2×6 |

5.5×4×7 |

Customized according to the actual situation |

|

Dry powder recovery (%) |

≥95 |

|||||